Plastic has ultra-high fluidity, which makes it difficult to produce the size of plastic injection parts in strict accordance with the requirements of the drawings, especially for some injection parts with high dimensional accuracy requirements, the dimensional accuracy of plastic injection parts refers to the size of the obtained plastic parts. The degree of conformity with the dimensions in the product drawings, that is, the accuracy of the dimensions of the plastic parts, how can we make products with high processing precision of injection molded parts?

First of all, there are many factors that affect the dimensional accuracy of plastic parts, the first is the mold manufacturing accuracy and the degree of wear of the mold, and the second is the fluctuation of plastic shrinkage and the change of process conditions during molding. The aging change after molding of the plastic part and the structure and shape of the mold, etc. Therefore, in order to reduce the processing difficulty of the mold and the manufacturing cost of the mold, the dimensional accuracy of the plastic part should be designed to be lower on the premise of meeting the requirements for the use of the plastic part.

The dimensional tolerance of plastic injection parts can be designed and processed according to the SJ1372-78 numerical standard for plastic parts tolerance. According to this standard, the injection precision of plastic parts is divided into 8 precision grades, of which 1 and 2 belong to the precision injection processing technology level. , only used under special requirements, the standard only specifies the standard tolerance value, and the basic size upper and lower deviation can be allocated according to the matching nature of the plastic parts.

For dimensions that are greatly affected by the movable part of the mold, such as the height dimension of the compression part, due to the influence of the thickness of the horizontal surface overflow, the tolerance value is the sum of the tolerance value and the additional value in the table, and the additional value of the 2-level accuracy It is 0.05mm, the additional value of 3~5 precision is 0.10mm, and the additional value of 6~8 precision is 0.20mm. In addition, for dimensions without tolerances, it is recommended to use the 8-level accuracy in the standard. Only by strictly producing according to the tolerance numerical standard of plastic injection parts can the dimensional accuracy and quality of plastic parts be guaranteed. In order to meet the pursuit of human beings for injection molding materials, the performance of products in various industries is constantly improving, and products are composed of accessories, which requires product accessories to be more and more precise, and maximize product accessories to meet the original design. The same is true for the size of the injection molding industry, and the precision injection molding process has become a field where major injection molding companies are competing.

Nowadays, many products are actually unable to reach the life of their original design. There are many reasons for this. One of the reasons is that the product accessories cannot reach the originally designed size. A complete product is composed of several or even upper It is composed of thousands of accessories, and the size fails to meet the design requirements, which makes problems in the process of use, and even if it takes a long time, the accessories should be replaced.

For example: every accessory on a spacecraft is manufactured through thousands of selections. Maybe a small size problem can lead to a major accident. Therefore, in recent years, various industries have increased their investment in precision manufacturing. Whoever masters the precise manufacturing technology will be able to dominate the future competition.

In recent years, the precision injection molding processing industry in the injection molding industry has developed rapidly, but what aspects are generally required to meet the conditions of precision injection molding processing?

One: It is the advanced injection molding machine equipment. The injection molding machine is the foundation of injection molding. If the foundation is not good, it will never produce good products.

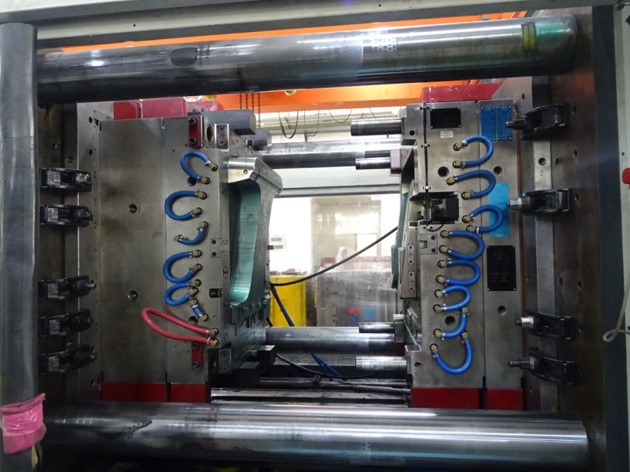

Second: the manufacture of molds, the injection molding industry is inseparable from molds, and molds with superior performance can add a lot of points to precision injection molding.

Third: injection molding operators, without an excellent injection molding engineer, no matter how good the equipment is, it is useless.

Fourth: the procurement of raw materials, the same plastic, its process is different, resulting in different performance of the plastic, injection molding.

|

|

online service

online serviceScan to wechat :