Injection Molding is a manufacturing process for producing parts in large volume. It is most typically used in mass-production processes where the same part is being created thousands or even millions of times in succession.

The principal advantage of plastic injection molding is the ability to scale production en masse. Once the initial costs have been paid the price per unit during injection molded manufacturing is extremely low. The price also tends to drop drastically as more parts are produced.

"The range of injection molding products involves: smart home products, auto parts, small household appliances, digital 3C products, medical products, power tools, etc.

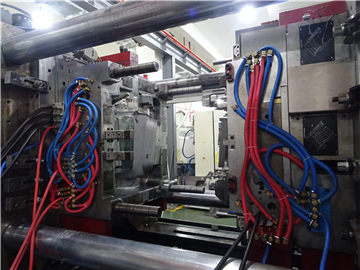

It has a clean and tidy workshop, with 25 injection molding machines ranging from 40 ton to 1300 ton, including 8 internationally renowned Toshiba electric high-speed injection molding machines, as well as advanced testing equipment. And has a group of experienced and skilled technicians. Under the perfect and scientific quality and management system, we guarantee a series of requirements of customers for high quality, low cost, short delivery time and so on.

|

|

|

|

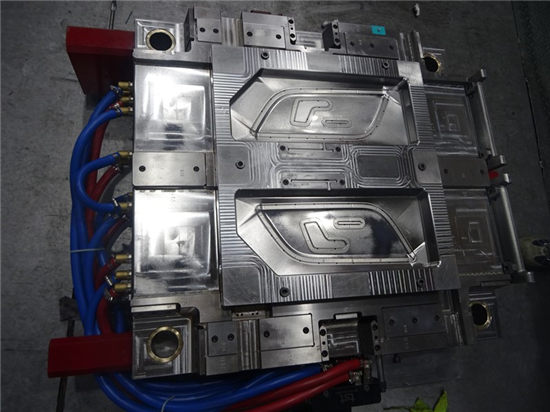

No design, no mold Rigorous scheme design, 96% of molds can be mass-produced in one trial

Analysis Through the analysis of material properties and product feasibility, such as wall thickness, deformation, glue feeding position, etc., pre-judgment of potential problems in advance

Communication Maintain close communication with customers, and understand the functional requirements and precautions of products from the perspective of customers, such as requirements for bonding lines, requirements for appearance, etc.

Strict design review system and checklist check. Before design, during the design of the proposal structure discussion meeting, the designer conducts self-check according to the checklist; after design, review together with the manufacturing department |

|

Mold Design Adjustments Quality inspection of each link, early detection of mass production problems

Our designers can make recommendations including material selection, wall thickness analysis, tooling, mold flow analysis, surface finish and part decoration based on our expertise.

|

|

Mould Manufacturing

Advanced technology, sophisticated equipment, manufacturing perfect high-quality molds!

|

|

|

High quality and excellent price We have won unanimous praise from customers for "high quality and excellent price"! "

The company's products are well-known in the domestic market, and are exported to Europe, America, Japan, Singapore and other countries and regions, and have won unanimous praise from customers for "high quality and excellent price"! "

Our plastic injection molding process produces custom prototypes and end-use production parts in 15 days or less. We use aluminum molds that offer cost-efficient tooling and accelerated manufacturing cycles, and stock about 200 different thermoplastic resins. |

online service

online serviceScan to wechat :