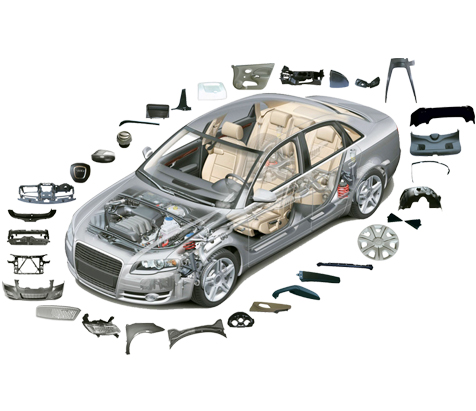

As a global professional automotive mould supplier, JHS researches and develops top grade mould with complex structure, high precision and technology content dependently focusing on automobile interior/exterior, blow and precision mould, In a word, theoptimization of auto parts and components circulation system is relative to all aspects.

R&D personnel are the source of innovation. Under the leadership of a strong R&D team, JHS has achieved outstanding achievements in scientific and technological projects. It has passed ISO 9001 certification and has been recognized as a national large-scale injection mold key enterprise. JHS has a production area of 10,000 square meters and is equipped with high-tech facilities. Currently, it has about 120 employees. We design mold structure data and continuously improve it during on-site machining, and adjust it according to 3D product data provided by customers, aiming to provide products with higher quality, better craftsmanship and stronger structure. Provide clear and high-quality 2D machining drawings for on-site processing, provide dimension and dimensional tolerance drawings for quality and process quantification of production and inspection, order standard parts that meet product standards, and finally provide customers with detailed and complete migration data.

online service

online serviceScan to wechat :