Product Origin:

Xiamen, ChinaLead Time:

Short mold development cycle

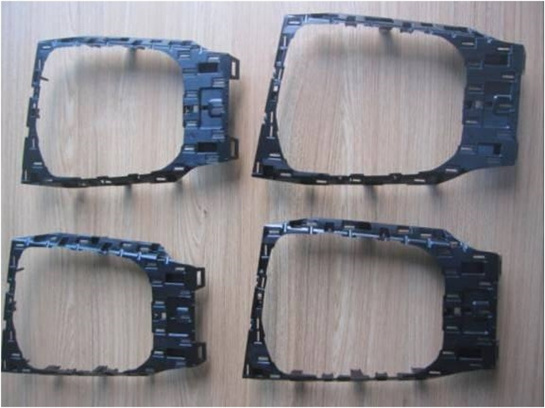

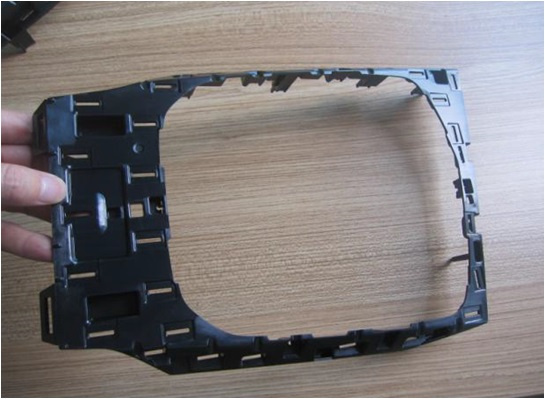

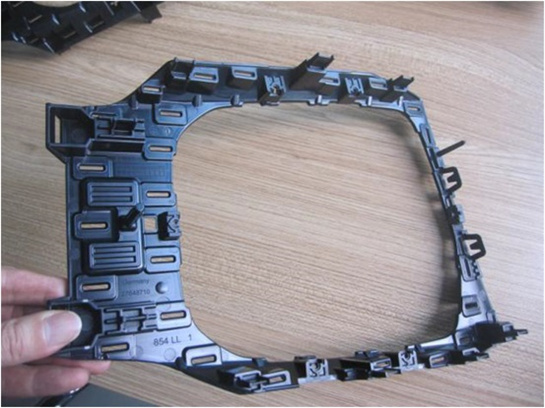

Automotive Frame Multi-Cavity Injection Mold

A multi-cavity mould can be understood, obviously referring to mold with multiple cavities. The multi-cavity mold comprises a multi-cavity of the same plastic part and a multi-cavity of different plastic parts.

Since the multi-cavity mould must have multiple runners to supply the melt to each cavity, the rationality of the injection molding system design directly affects the quality of the injection molded parts, material consumption, production efficiency and economic benefits.

In order to ensure the uniformity and performance of the quality and performance of each cavity, the flow balance of the gating system during the injection process is very critical, so that the plastic melt can be filled the cavity with the same pressure and temperature at the same time. Therefore, filling balance is the most important factor to consider when designing a multi-cavity mould.

The arrangement of the cavity and the runner is divided into two categories: balanced and unbalanced.

The feature of balance type is the length, shape and section dimension of the runner from the sprue to each cavity are correspondingly the same, it can realize even feeding of all cavities and fill the cavity at the same time. However, the unbalanced feature is that the lengths of the runners from the sprue to the cavity gates are not equal, which is not conducive to balanced feeding, but the unbalanced arrangement can significantly shorten the overall flow of the melt in the gating system. The compact mechanism reduces heat loss and injection pressure loss during flow and shortens the mold filling time.

| Name | Automotive Frame Mould |

| Mold size | Custom Size |

| Mould material | 45#,50#,1.2312 ,1.2343 ESR,1.2738 HH , S136 ,NAK80 , SKD61 etc. |

| Mould base | LKM, HASCO ect. |

| Cavity | Single/multi |

| Runner | Hot/cold |

| Design software | UG, PROE, CAD, CAXA ect. |

| Mould life | 300,000-3,000,000 shots |

| Delivery time | 15-60days |

| Specification | Depends on customer's requirments |

| Shaping Mode | Plastic Injection Mould |

| Molding life | 500,000-5,000,000shots |

| Delivery time | Short mold development cycle |

| Packing | Standard exporting wooden case |

1) Receive customer's inquiry

2) We will quote guests within 24 hours

3) Confirm the order (price, payment terms, delivery date)

4) Product analysis (DFM)

5) After DFM confirmation by customer

6) Confirmation of mold design

7) Purchase steels and start machining processing

8) Inspection process

9) Mold core inspection is OK, start assembly

10) Tool tryout and deliver the samples to customer

11) Get feedback of samples from customer.

12) If there is a problem with the sample, repair the mold

13) After repaired , tryout and deliver samples to customer for confirmation again

14) After the sample is confirmed that there is no problem, the mold is arranged to be shipped

Please send 3D/2D drawing or samples to us if you have any needs, we will quote for free with a sound price.

We focus on:

As a service to our customers' moulds, our moulds are made in-house

We will work from prints or samples

Turnaround time to meet your needs

Premium custom molding from start-up to delivery

Provide product design assistance

Provide professional engineering services

Rich experience in consumer electronics design

Provide mold design services

Design for manufacturability service

Provide mold flow analysis service

Provide product testing services

Provide material testing and validation services

Provide product development services

Early Engineering Support

Quality Requirements Plan

Material selection consultation

Tooling Concept Planning

Personalized service for every customer

JHS is committed to the research and development, design and manufacture of various injection molds, and injection production, involving industries and fields such as electronics, automobiles, communications and household appliances.

CNC Machining Workshop

EDM Workshop

Quality Inspection Department

Wire Cutting Workshop

Injection Workshop

Assembly Workshop

Q: Do you make molds for many auto parts?

A: Yes, we make molds for many auto parts, such as bumpers, reversing radar parts, car control panels, rearview mirror brackets, etc.

Q: Do you have injection molding machines to produce parts?

A: Yes, we have our own injection workshop, so we can produce and assemble according to customer requirements.

Question: What kind of mold do you make?

A: We mainly manufacture injection molds, but we can also manufacture compression molds (for UF or SMC materials) and die casting molds.

Q: How long does it take to make a mold?

A: Depending on the product size and the complexity of the parts, it is slightly different. Generally speaking, a medium-sized mold can complete T1 within 25-30 days.

Q: Can we know the mold schedule without visiting your factory?

A: According to the contract, we will send you the mold production plan. During the production process, we will update you with weekly reports and related pictures. Therefore, you can clearly understand the mold schedule.

Q: How do you guarantee the quality?

A: We will appoint a project manager to track your molds, and he will be responsible for each process. In addition, we have QC for each process, and we will also have a CMM and online inspection system to ensure that all components are within tolerance.

Q: Do you support OEM?

A: Yes, we can produce through technical drawings or samples.

online service

online serviceScan to wechat :