Product Origin:

Xiamen, ChinaLead Time:

Short mold development cycle

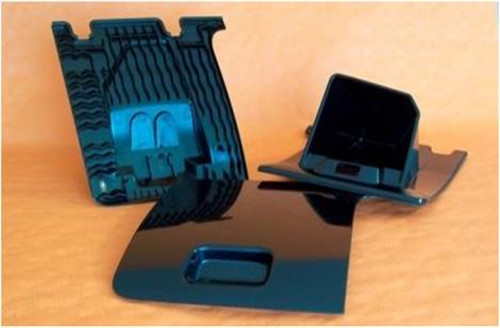

Factory direct OEM Automotive storage box mould

China specializes in plastic molds, car console injection mold manufacturers

JHS Mould has a strong design team to accept: provide samples, or, 3D drawings, 2D drawings, can quote for mold opening, you are welcome to consult and quote!

A variety of mold materials for your choice!

For Interior mold tooling, high precision is very important.Such as door trims products have high requirements on the appearance. We also make dashboard mould, door inner panel mould, AB boss mould.

Usually, door trim will be requested for texture. On the product, it can not appear welding line, ejector white mark, shrinkage mark, and deformation. And we have rich experience in making these moulds,we know how to make the best design for them.And below is the regular specification for car door trim mould.

| Name | factory direct OEM Automotive storage box mould |

| Mold size | Custom Size |

| Mould material | 45#,50#,1.2312 ,1.2343 ESR,1.2738 HH , S136 ,NAK80 , SKD61 etc. |

| Mould base | LKM, HASCO ect. |

| Cavity | Single/multi |

| Runner | Hot/cold |

| Design software | UG, PROE, CAD, CAXA ect. |

| Mould life | 300,000-3,000,000 shots |

| Delivery time | 15-60days |

| Specification | Depends on customer's requirments |

| Shaping Mode | Plastic Injection Mould |

| Molding life | 500,000-5,000,000shots |

| Delivery time | Short mold development cycle |

| Packing | Standard exporting wooden case |

1) Receive customer's inquiry

2) We will quote guests within 24 hours

3) Confirm the order (price, payment terms, delivery date)

4) Product analysis (DFM)

5) After DFM confirmation by customer

6) Confirmation of mold design

7) Purchase steels and start machining processing

8) Inspection process

9) Mold core inspection is OK, start assembly

10) Tool tryout and deliver the samples to customer

11) Get feedback of samples from customer.

12) If there is a problem with the sample, repair the mold

13) After repaired , tryout and deliver samples to customer for confirmation again

14) After the sample is confirmed that there is no problem, the mold is arranged to be shipped

Please send 3D/2D drawing or samples to us if you have any needs, we will quote for free with a sound price.

|

|

1. We have been engaged in mold field for more than 13 years and have much experience in manufacturing plastic injection mold, precision parts mold etc.

2. We are market-leader in this line in mold aspects in China.

3. Reasonable collocation to molds to save cost

4. Mold design is decided by customer’s requests.such an cycle time.employee quantity.mold machine specification.shrinkage of certain plastic material ect.

5. Mold making processes can be tracking according to schedule

6. We are always searching technical commucation with our customers.The purpose is to prevent misunderstanding and modification after fineshing molds.

7. We can supply you the schedule report.inspection report’.warranty of every mold and the video for the mold

8. We will reply your inquiry within 24 hours.

JHS is committed to the research and development, design and manufacture of various injection molds, and injection production, involving industries and fields such as electronics, automobiles, communications and household appliances.

CNC Machining Workshop

EDM Workshop

Quality Inspection Department

Wire Cutting Workshop

Injection Workshop

Assembly Workshop

Q: Do you make molds for many auto parts?

A: Yes, we make molds for many auto parts, such as bumpers, reversing radar parts, car control panels, rearview mirror brackets, etc.

Q: Do you have injection molding machines to produce parts?

A: Yes, we have our own injection workshop, so we can produce and assemble according to customer requirements.

Question: What kind of mold do you make?

A: We mainly manufacture injection molds, but we can also manufacture compression molds (for UF or SMC materials) and die casting molds.

Q: How long does it take to make a mold?

A: Depending on the product size and the complexity of the parts, it is slightly different. Generally speaking, a medium-sized mold can complete T1 within 25-30 days.

Q: Can we know the mold schedule without visiting your factory?

A: According to the contract, we will send you the mold production plan. During the production process, we will update you with weekly reports and related pictures. Therefore, you can clearly understand the mold schedule.

Q: How do you guarantee the quality?

A: We will appoint a project manager to track your molds, and he will be responsible for each process. In addition, we have QC for each process, and we will also have a CMM and online inspection system to ensure that all components are within tolerance.

Q: Do you support OEM?

A: Yes, we can produce through technical drawings or samples.

online service

online serviceScan to wechat :